Short Lead Time for Scx Resin - Injection&Labelling For Frozen Pipes – BM Life Science

Short Lead Time for Scx Resin - Injection&Labelling For Frozen Pipes – BM Life Science Detail:

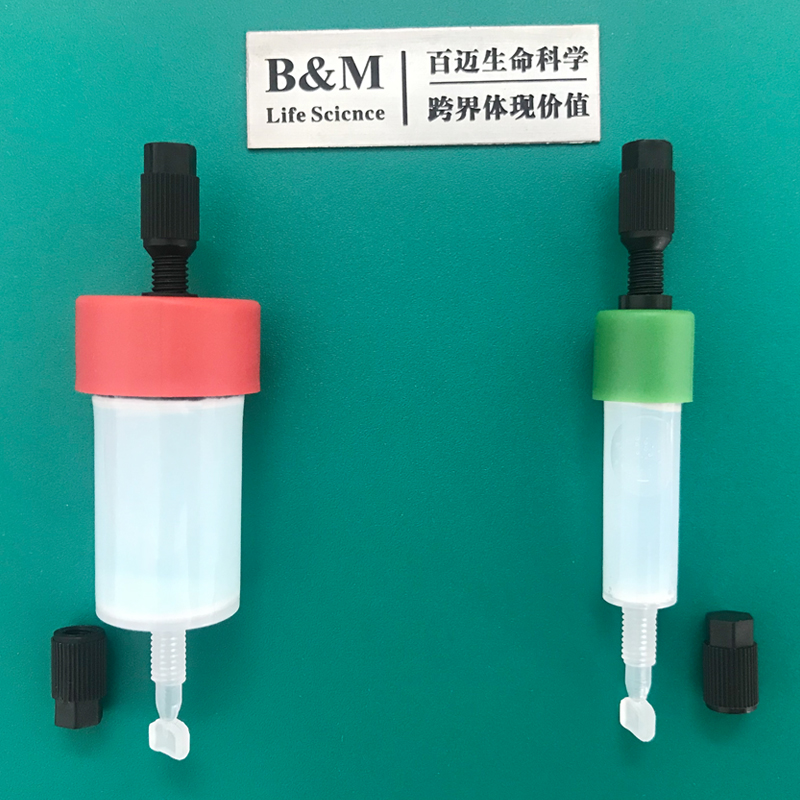

Injection&Labelling For Frozen Pipes

①Product Parameter

Product Category: Automatic Instrument for Frozen Pipes to Injection&Labelling

Function: : Injection&Labelling for 2ml erectable tube & frozen pipes

Channel number: 1-4 channel separator(Optional)

Method of feeding: vibrator or ladder

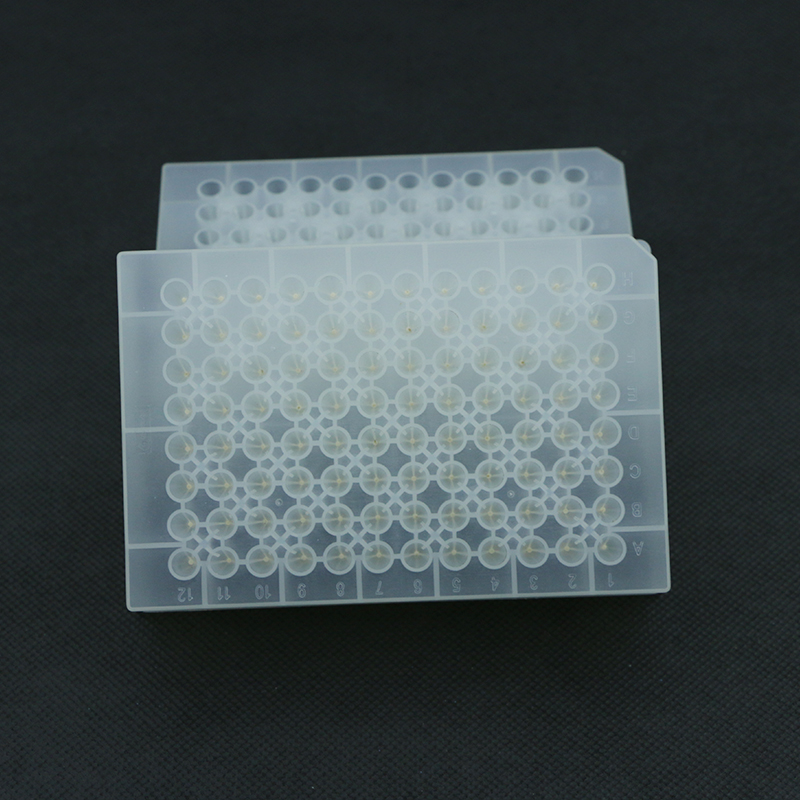

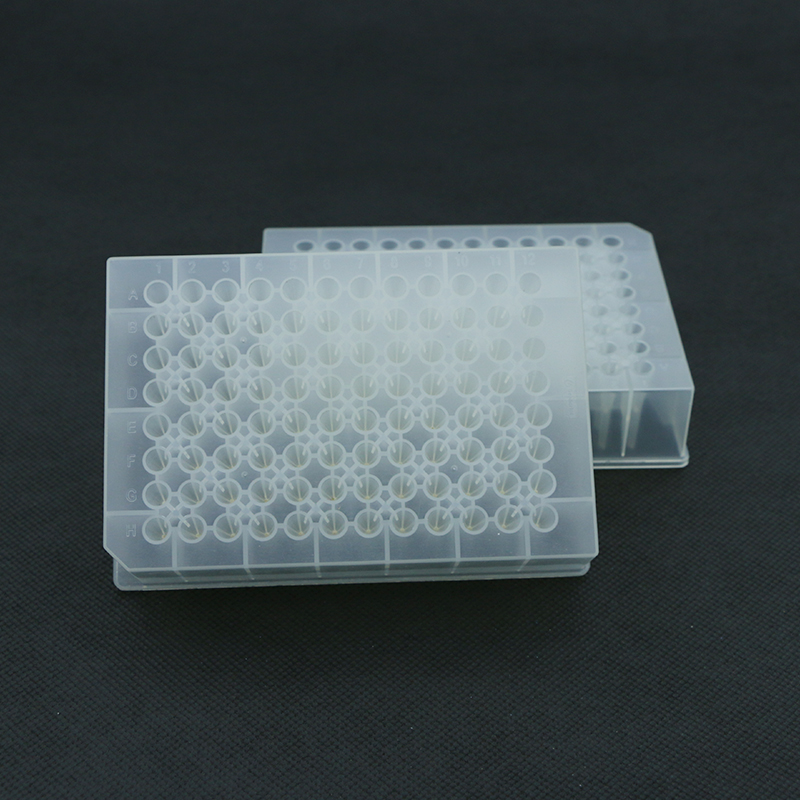

Specification:1.5ml Centrifugal, 2ml erectable tube, 15ml Centrifugal, 50ml Centrifugal, one or more of the various reagent bottles for liquid separation, sampling, real-time marking, labelling, cover, pipe cover spray code and pendulum

Printing LOGO:OK

Mode of supply:OEM/ODM

②Description of products

The instrument is a fully automatic sampling,injection,printing label,labelling,rotating covers, and arrangement integration machine specially designed for the production of in vitro diagnostic reagents in the field of life science. It is a non-standard custom equipment. Suitable for 2 ml tube cover separation type of standable tube splicing,injection, labelling, covering and pallet.

The biggest bright points of this instrument is the equivalent of a reagent assembly line in the IVD industry(separation, labelling, labelling, packaging, etc. of reagents such as Enzymes, Mix, Buffer, etc.). This pipeline is only automatically operated on the same device with a volume of nearly 2 cubic meters, which can greatly improve the production efficiency of IVD manufacturers, reduce the cost of enterprise management and operation, increase the core competitiveness of enterprises, and speed up the industrialization process of the industry. And then promote the development of the entire industry!

The equipment has intelligent control, automatic photoelectric tracking, accurate liquid separation, nothing without labeling, no standard automatic correction and label automatic detection function, to prevent leakage and label waste; At the same time, it has the function of positioning labels and automatic placement boxes, greatly improving production efficiency, and achieving a design capacity of 400-1300 PCS/H.

③Product characteristics

★Divide accuracy:Control by imported precision solenoid valve, with sample error range ± 5 %, using the compressed inert gas as the power medium.

★Separation time: 500 UL, within 5 seconds; 1 ML, 10 seconds.

★The device can be matched with commercially available label printers(carbon belt printing type, such as zebra Zebra 110Xi 4/ZM400/105sl, TSC, etc.), which can form an integrated machine and achieve real-time printing and labeling. The operation is extremely convenient.

★The device can be customized according to customer requirements, such as equipped with a laser jet code printer, jet code location can choose tube body or tube cover. Or Tianjiagai cap or spin cover and other functions. Or use a computer full control system.

★The adjustment of the machine is simple, and the injection,printing label,labelling,rotating covers, and pendulum speed can be adjusted without grading, and can be adjusted as needed.

★The machine is made of stainless steel and advanced aluminum alloy. The machine has a long service life and few pollution sources. It can meet the related environmental requirements of the biological industry.

Order information

|

Name |

Describe |

Specification |

| Instrument For Injection&Labelling | Centrifuge Tube Labeller | 1.5ml Centrifuge Tube Labeller |

| Labelling For Frozen Pipes | 2ml Frozen Pipe Labeller | |

| Injection&Labelling For Frozen Pipes | 2ml Frozen Pipe Injection&Labelling |

More specifications or personalized customizations, welcome all new and old customers to inquire, discuss cooperation, seek common development!

Product detail pictures:

Related Product Guide:

Global Sintered Porous Metal Filters Market Comprehensive Insights, New Project Investment and Growth Potential In The Future | Waters Quechers Dispersive Absorbent

Global Sintered Metal Filters Market Analysis By Supplier, Manufacturer, and Industry Players(2019-2028) | Waters Quechers Dispersive Absorbent

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for Short Lead Time for Scx Resin - Injection&Labelling For Frozen Pipes – BM Life Science , The product will supply to all over the world, such as: Amman, Rwanda, India, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.