OEM/ODM Factory Automated Evaporation System - Plastic Syringe Filters – BM Life Science

OEM/ODM Factory Automated Evaporation System - Plastic Syringe Filters – BM Life Science Detail:

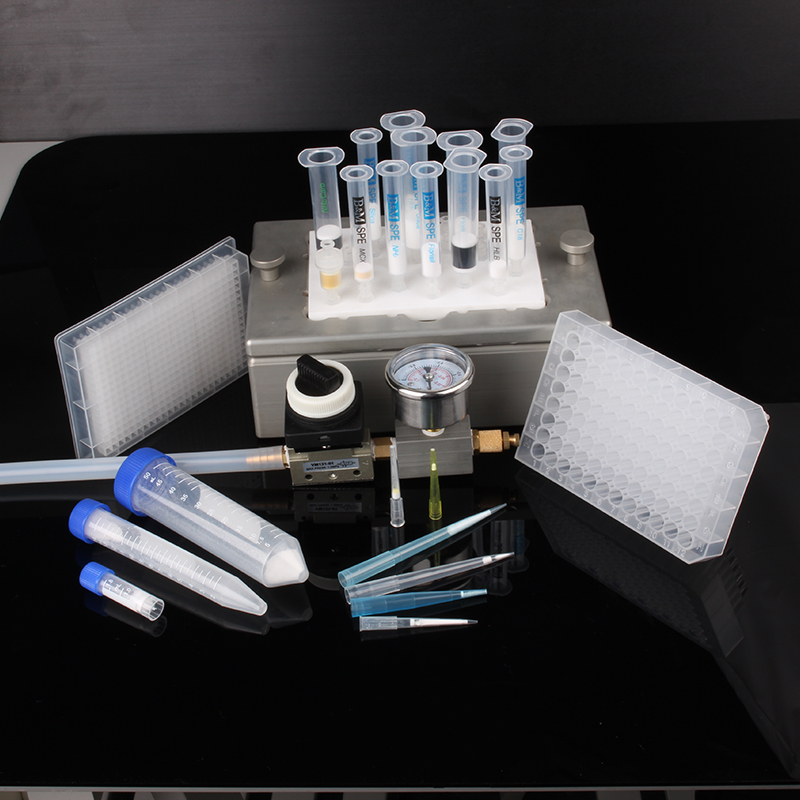

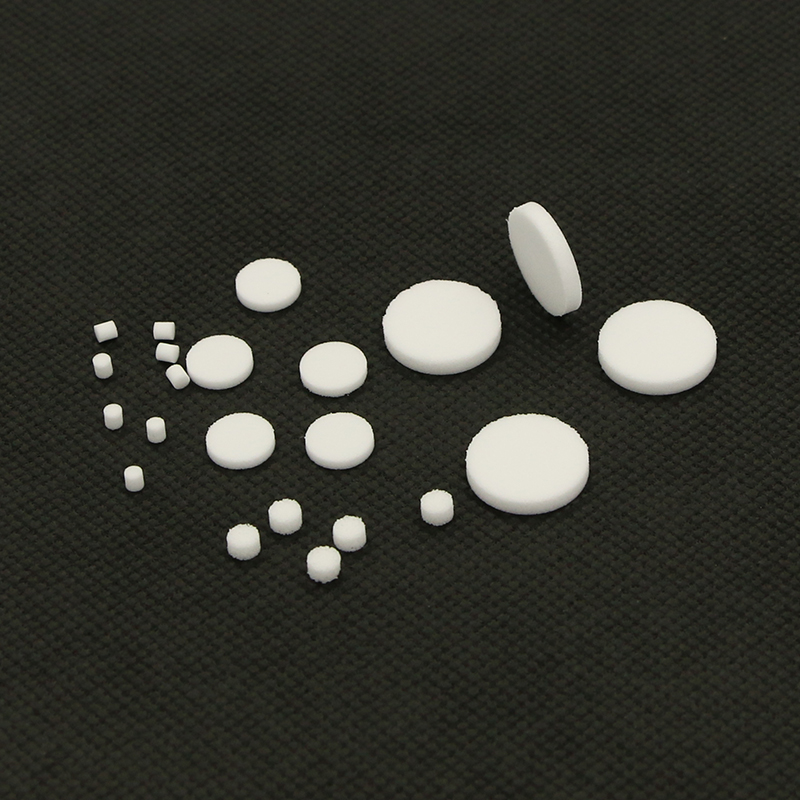

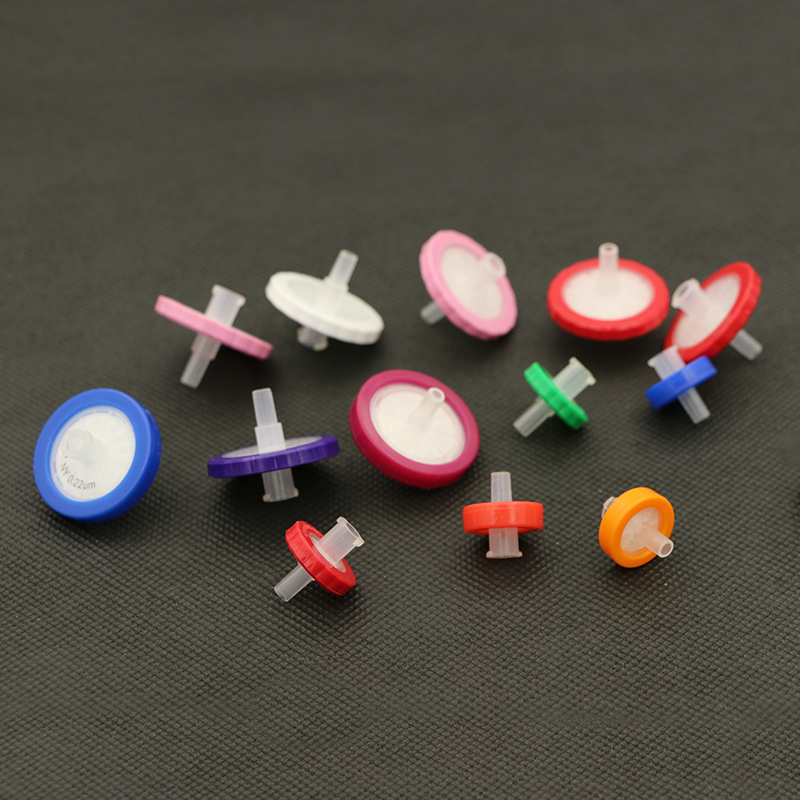

Syringe filter is a quick, convenient and reliable filter tool used routinely in the laboratory.Because they don’t need to change the membrane and filter cleaning, it’s eliminating the complex and time-consuming preparation. It is widely used in the sample pre filtration, removal of particles, aseptic filtration of liquids and gases. It is the preferred method to filter small samples before loading into HPLC and GC ,and it is often used with disposable syringe. The filter diameter is 4mm ~ 50mm, and the processing capacity is from 0.5ml ~ 200ml.

We can provide OEM service according to customer demand. The batch difference is very little. There is a strict quality control SOP from raw materials to production to outbound delivery. It ensures the maximum product quality and usage. Common membranes of various specifications are available:PES/PTFE/Nylon/MCE/GF/PVDF/CA etc.The pore size is from 0.1um to 5um;The OD is 4mm/13mm/17mm/25mm/30mm/47mm etc.

Product Features

|

Membrane Material |

Main Performance |

|

Nylon |

①Resistance to strong alkali and organic solvent,Natural hydrophily;②No infiltration is required before use;③Uniform pore,Good mechanical strength;④Thread interface design. |

|

MCE |

①High porosity and good intercepting effect;②Not resistant to strong acids,strong alkali solutions and most organic solvents;③Most suitable for filtration of aqueous solutions;④Unique Thread interface design. |

|

CA |

①Natural hydrophily;②Low protein adhesion, suitable for aqueous solution treatment;③Nitrate free, suitable for groundwater filtration;⑤Uniform bore structure;⑥Extensive aperture select;⑦Keep the collection of granular cells. |

|

PES |

①High solvent recovery and little residue;②High capacity;③Extremely high microbial filtration capacity;④Unique Thread interface design;⑤Low protein adsorption, low dissolution. |

|

PVDF |

①Hydrophobic film, non – moisture absorption, easily steady weight;②Heat resistance and repeated heat pressure disinfection;③Resistant to chemical corrosion and oxidation. |

|

PTFE |

①Excellent chemical resistance;②Resistant to high temperature, strong acid and strong alkali, with strong hydrophobicity;③Hydrophilic film and hydrophobic film can be provided to meet different liquid filtration requirements. |

|

GF |

①Natural hydrophobicity;②Large Flux;③Carrying large dirty matter; ④Good mechanical strength. |

|

Application |

1. Removal of protein precipitate and dissolution assay;2.Analysis of beverage and food and analysis of biofuels;3.Sample pretreatment;4. Environmental monitoring and analysis;5. Analysis of pharmaceutical and pharmaceutical products;6. Liquid phase gas chromatography sample preparation and specific QC analysis;7. Gas filtration and fluid detection. |

|

Syring filter |

Membrane Material |

Diameter(mm) |

Pore Size(um) |

|

Nylon |

Nylon |

13, 25, 33 |

0.22, 0.45,0.8 |

|

MCE |

MCE |

13, 25, 33 |

0.22, 0.45,0.8 |

|

CA |

CA |

13, 25, 33 |

0.22, 0.45 |

|

PES |

PES |

13, 25, 33 |

0.22, 0.45,0.8 |

|

PVDF |

PVDF |

13, 25, 33 |

0.22, 0.45,0.8 |

|

PTFE |

PTFE |

13, 25, 33 |

0.22, 0.45,0.8 |

|

GF |

GF |

13, 25 |

0.7,1.0 |

|

PP |

PP |

13, 25, 33 |

0.22, 0.45 |

Ordering information

| Cat.# | description(Membrane Material/Diameter/Pore Size/Solvent compatibility) | Qty. |

| BM-NL-130-22 | Nylon/Ф13mm/0.22μm/Organic | 100/box |

| BM-NL-130-45 | Nylon/Ф13mm/0.45μm/Organic | 100/box |

| BM-NL-130-80 | Nylon/Ф13mm/0.8μm/Organic | 100/box |

| BM-NL-250-22 | Nylon/Ф25mm/0.22μm/Organic | 100/box |

| BM-NL-250-45 | Nylon/Ф25mm/0.45μm/Organic | 100/box |

| BM-NL-250-80 | Nylon/Ф25mm/0.8μm/Organic | 100/box |

| BM-NL-330-22 | Nylon/Ф33mm/0.22μm/Organic | 100/box |

| BM-NL-330-45 | Nylon/Ф33mm/0.45μm/Organic | 100/box |

| BM-NL-330-80 | Nylon/Ф33mm/0.8μm/Organic | 100/box |

| BM-MCE-130-22 | MCE/Ф130mm/0.22μm/Aqueous | 100/box |

| BM-MCE-130-45 | MCE/Ф130mm/0.45μm/Aqueous | 100/box |

| BM-MCE-130-80 | MCE/Ф130mm/0.8μm/Aqueous | 100/box |

| BM-MCE-250-22 | MCE/Ф250mm/0.22μm/Aqueous | 100/box |

| BM-MCE-250-45 | MCE/Ф250mm/0.45μm/Aqueous | 100/box |

| BM-MCE-250-80 | MCE/Ф250mm/0.8μm/Aqueous | 100/box |

| BM-MCE-330-22 | MCE/Ф330mm/0.22μm/Aqueous | 100/box |

| BM-MCE-330-45 | MCE/Ф330mm/0.45μm/Aqueous | 100/box |

| BM-MCE-330-80 | MCE/Ф330mm/0.8μm/Aqueous | 100/box |

| BM-CA-130-22 | CA/Ф130mm/0.22μm/Aqueous | 100/box |

| BM-CA-130-45 | CA/Ф130mm/0.45μm/Aqueous | 100/box |

| BM-CA-250-22 | CA/Ф250mm/0.22μm/Aqueous | 100/box |

| BM-CA-250-45 | CA/Ф250mm/0.45μm/Aqueous | 100/box |

| BM-CA-330-22 | CA/Ф330mm/0.22μm/Aqueous | 100/box |

| BM-CA-330-45 | CA/Ф330mm/0.45μm/Aqueous | 100/box |

| BM-PES-130-22 | PES/Ф13mm/0.22μm/Aqueous | 100/box |

| BM-PES-130-45 | PES/Ф13mm/0.45μm/Aqueous | 100/box |

| BM-PES-130-80 | PES/Ф13mm/0.8μm/Aqueous | 100/box |

| BM-PES-250-22 | PES/Ф25mm/0.22μm/Aqueous | 100/box |

| BM-PES-250-45 | PES/Ф25mm/0.45μm/Aqueous | 100/box |

| BM-PES-250-80 | PES/Ф25mm/0.8μm/Aqueous | 100/box |

| BM-PES-330-22 | PES/Ф33mm/0.22μm/Aqueous | 100/box |

| BM-PES-330-45 | PES/Ф33mm/0.45μm/Aqueous | 100/box |

| BM-PES-330-80 | PES/Ф33mm/0.8μm/Aqueous | 100/box |

| BM-PVDF-130-22 | PVDF/Ф13mm/0.22μm/Organic | 100/box |

| BM-PVDF-130-45 | PVDF/Ф13mm/0.45μm/Organic | 100/box |

| BM-PVDF-130-80 | PVDF/Ф13mm/0.8μm/Organic | 100/box |

| BM-PVDF-250-22 | PVDF/Ф25mm/0.22μm/Organic | 100/box |

| BM-PVDF-250-45 | PVDF/Ф25mm/0.45μm/Organic | 100/box |

| BM-PVDF-250-80 | PVDF/Ф25mm/0.8μm/Organic | 100/box |

| BM-PVDF-330-22 | PVDF/Ф33mm/0.22μm/Organic | 100/box |

| BM-PVDF-330-45 | PVDF/Ф33mm/0.45μm/Organic | 100/box |

| BM-PVDF-330-80 | PVDF/Ф33mm/0.8μm/Organic | 100/box |

| BM-PTFE-130-22 | PTFE/Ф13mm/0.22μm/Organic | 100/box |

| BM-PTFE-130-45 | PTFE/Ф13mm/0.45μm/Organic | 100/box |

| BM-PTFE-130-80 | PTFE/Ф13mm/0.8μm/Organic | 100/box |

| BM-PTFE-250-22 | PTFE/Ф25mm/0.22μm/Organic | 100/box |

| BM-PTFE-250-45 | PTFE/Ф25mm/0.45μm/Organic | 100/box |

| BM-PTFE-250-80 | PTFE/Ф25mm/0.8μm/Organic | 100/box |

| BM-PTFE-330-22 | PTFE/Ф33mm/0.22μm/Organic | 100/box |

| BM-PTFE-330-45 | PTFE/Ф33mm/0.45μm/Organic | 100/box |

| BM-PTFE-330-80 | PTFE/Ф33mm/0.8μm/Organic | 100/box |

| BM-GF-250-046 | GF/Ф25mm/0.46μm/Aqueous | 100/box |

| BM-GF-250-080 | GF/Ф25mm/0.8μm/Aqueous | 100/box |

| BM-PP-**-** | pp/Ф**mm/**μm/Organic,Please ring for assistance | 100/box |

| BM-MET-130 | Metal/Ф13mm/Replaceable membrane | 1/box |

| BM-MET-250 | Metal/Ф25mm/Replaceable membrane | 1/box |

| Other specifications or Materials.Please ring for assistance | ||

Product detail pictures:

Related Product Guide:

Global Bumper Reflectors Market 2019 – Replacement, Omix, Dorman, Depo, Auto Metal Direct, Genuine, Goodmark, K-Metal, Sherman, He | Bespoke Microfiltration Membrane

Fill-finish Manufacturing Market Global Opportunity Analysis and Forecast 2017 – 2025 | Sintered Metal Filters

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for OEM/ODM Factory Automated Evaporation System - Plastic Syringe Filters – BM Life Science , The product will supply to all over the world, such as: Canada, Venezuela, Johannesburg, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.