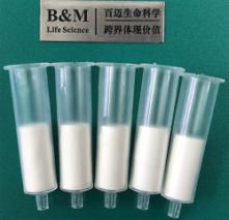

The pipette filter is made of ultra-high molecular polyethylene powder (UHMWPE) with a certain particle size through a special sintering process. The product has excellent chemical resistance, organic solvent resistance and biological inertness. It can prevent liquid or aerosol from moving inside the filter and prevent it from entering the pipette and causing pipette contamination. At the same time, it can also prevent impurities in the pipette from contaminating the sample. The pipette plus filter tip can effectively prevent cross-contamination between samples and effectively block the harm caused by dangerous samples to experimenters. Therefore, pipette filter tips are widely used in the pre-processing applications of global coronavirus samples.

BM Life Science, as an innovator of the overall solution for sample pretreatment and testing, spares no effort in the development and production of pipette filter element series products. Innovatively developed three sets of pipette filter element production processes, which can provide the world’s smallest filter element with a diameter as low as 0.25mm and an ultra-large filter element with a diameter of 7.0mm and a thickness of 50mm or more. The pore size of the filter element can be custom-made,which is ranging from 1 to 100um.

All the raw materials used in the production of pipette filter elements are imported and specially optimized, with uniform particle size, good air permeability and high dimensional accuracy. All links are clean-room production, assembly line operation, optical robot quality inspection, entirely ERP management, ultra-pure products, no DNase/RNase, no PCR inhibitors, and no heat source. Pipette filter element series products in BM Life Science can be all customized. The series of full specifications of filter element products have stable batches and small inter-batch differences with high quality and are widely exported to Japan, South Korea, Europe and the United States, applying to all kinds of pipette tips!

Post time: Apr-23-2022